Integrating IoT to Enhance Aluminum Window Performance

🌍 1. The Global Shift Toward Smart Homes

The global smart home market is projected to exceed US$200 billion by 2026, driven by automation, energy efficiency, and enhanced security demands. Aluminium doors and windows — once purely structural elements — are now being redefined as active components of connected living spaces.

💡 IoT Integration = New Market Value for Aluminium Windows

🔐 2. From Passive Frames to Smart Guardians

Modern aluminium windows now incorporate sensors, microchips, and wireless modules, allowing them to:

• Detect window status (open/close)

• Monitor temperature and humidity

• Integrate with smart locks and alarm systems

• Trigger ventilation or shading automatically

🏠 Smart aluminium windows are no longer just protection — they’re participation in home intelligence.

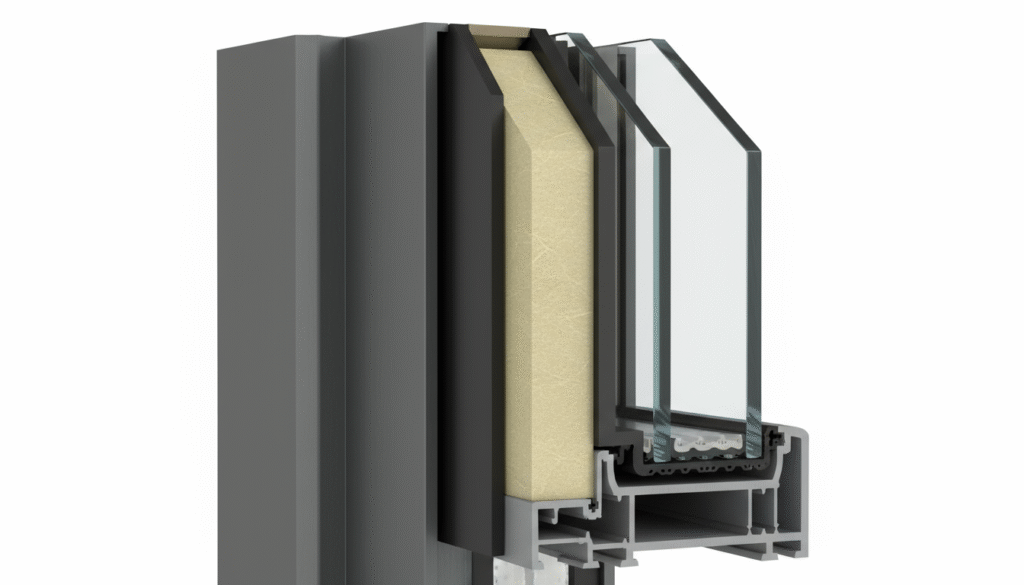

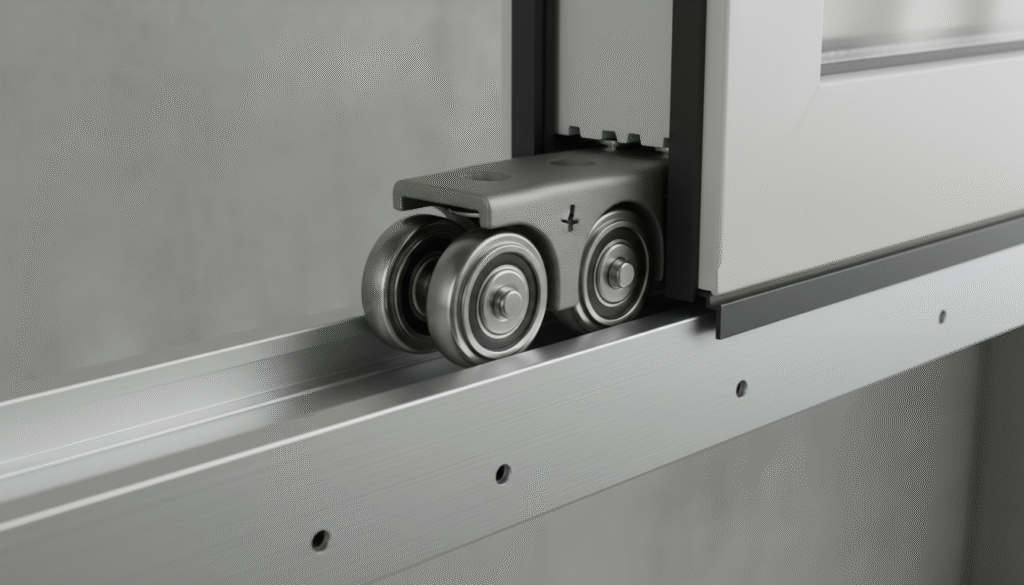

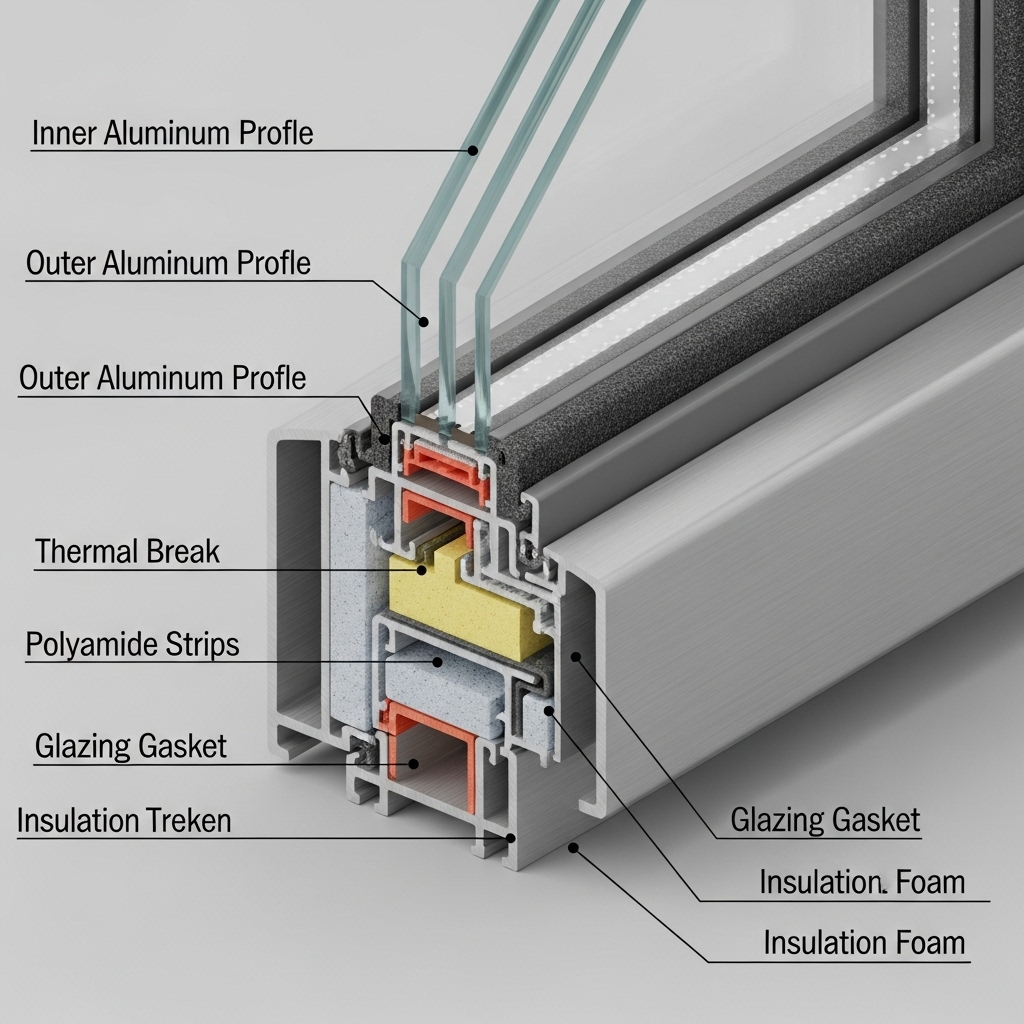

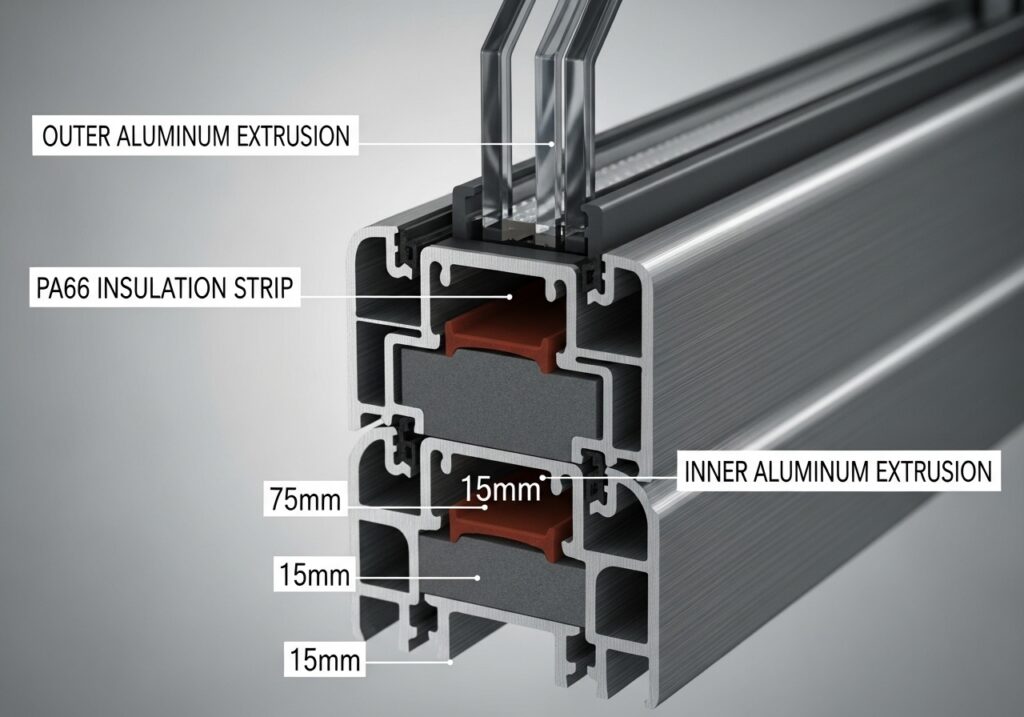

⚙️ 3. Why Aluminium Is Ideal for Smart Integration

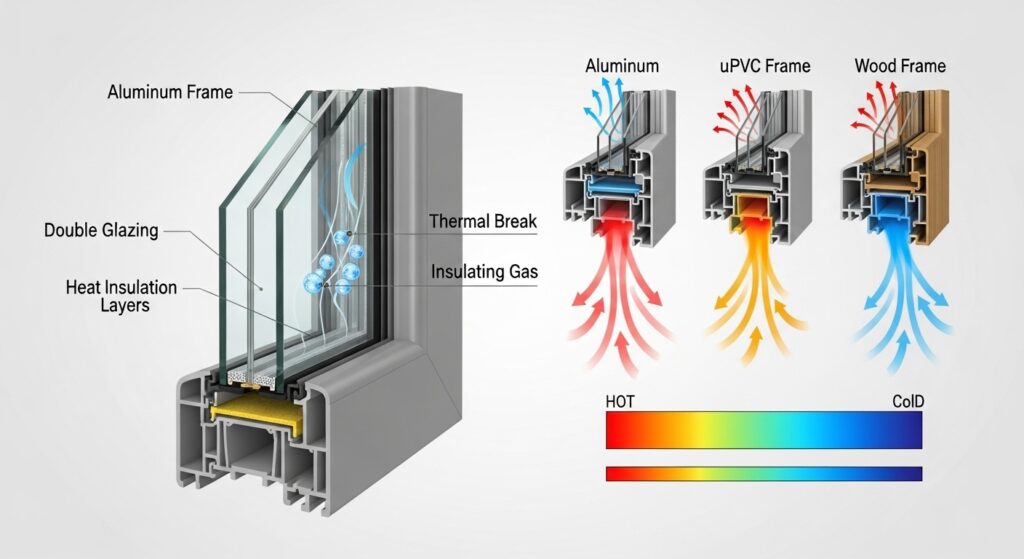

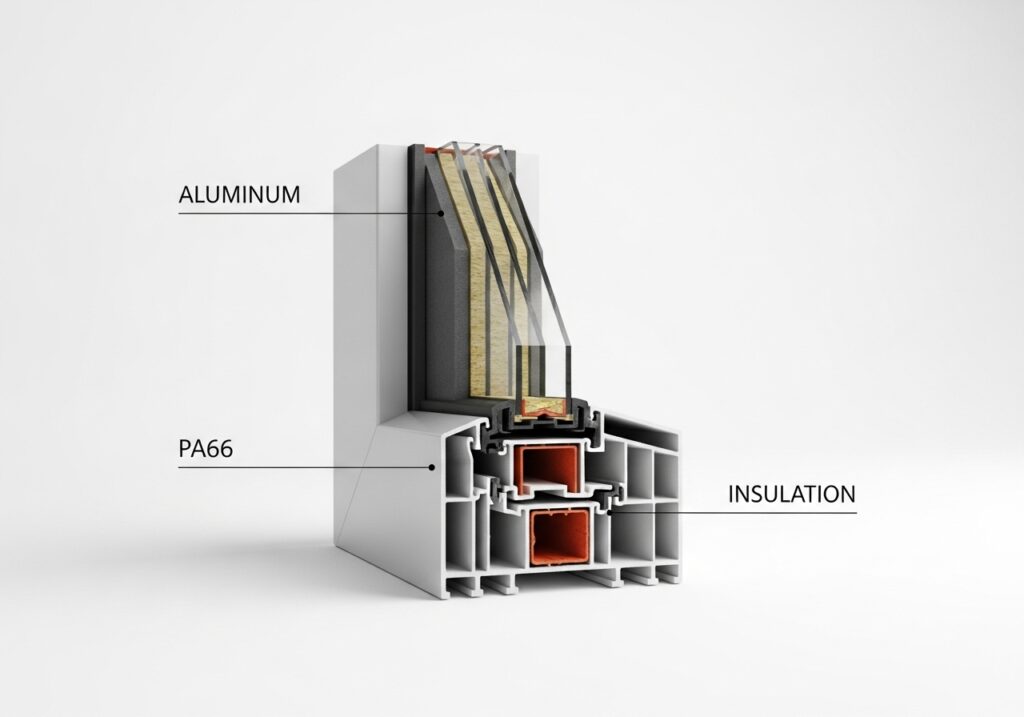

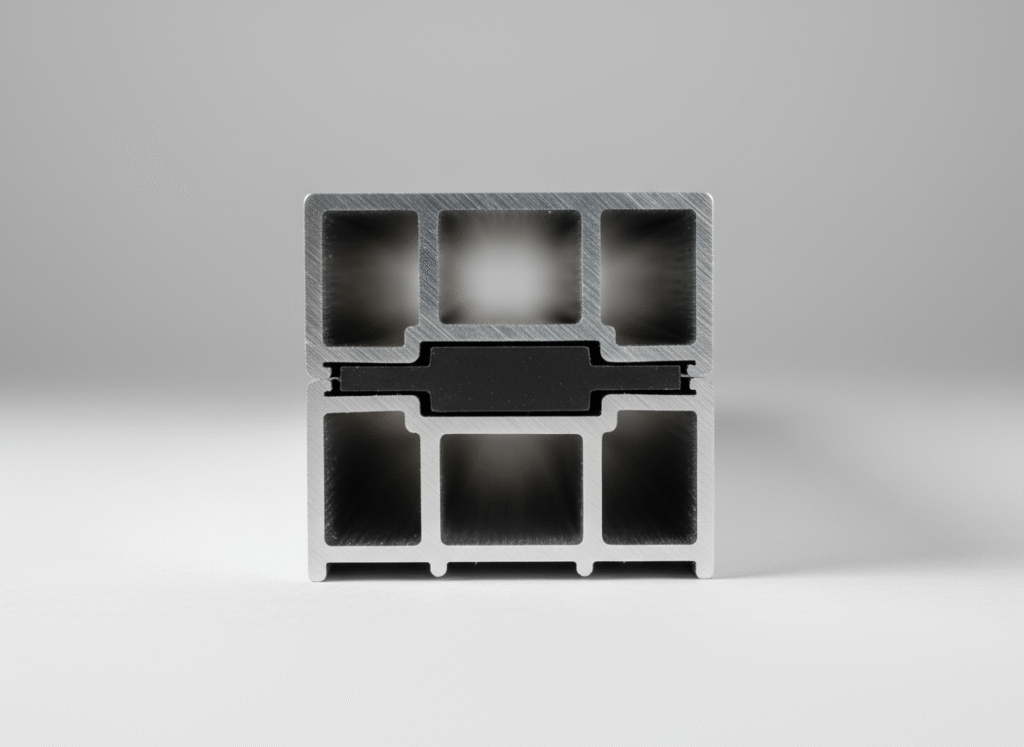

Aluminium provides the strength, flexibility, and heat resistance required for integrating electronics without compromising structure.

Additionally, thermal break technology ensures insulation, while surface anodizing or powder coating prevents interference with wireless signals.

🧠 Strong + Smart = Sustainable

🔋 4. Cost and Feasibility: What Buyers Should Know

While early smart window systems were expensive, advances in low-cost sensors and modular smart hubs have made integration affordable.

For large projects in the Middle East, Africa, and Southeast Asia, integrating IoT features during manufacturing can reduce retrofitting costs and appeal to green building certifications.

📊 Buyers should evaluate long-term energy savings vs. initial investment.

🧠 5. The Future: AI-Driven Maintenance & Predictive Safety

The next generation of aluminium windows will feature AI algorithms that predict wear, track user behavior, and alert owners before mechanical failure.

Imagine a window that tells you when its hinges need lubrication — or when high wind pressure requires temporary locking.

🌐 Smart windows are evolving from passive design to proactive intelligence.

🏗️ 6. Openhaus: Pioneering Smart Aluminium Solutions

With over 10 years of aluminium manufacturing experience, Openhaus is ready to support global builders and distributors embracing the IoT era.

Our team integrates custom smart modules, durable structures, and export-ready packaging, ensuring every shipment arrives with precision and reliability.

🚀 Smart manufacturing meets global trade — that’s the Openhaus way.

📚 Conclusion

Smart aluminium windows are not just the future — they are already shaping how we live, build, and connect.

As IoT technologies mature, those who adopt early — like Openhaus — will lead the next decade of energy-efficient and intelligent architecture.

📞 Contact Openhaus

📧 Email: openhausliving@gmail.com

🌐 Website: https://openhausliving.com

🔺 YouTube: https://youtube.com/@openhausliv?si=dktMp7xiL4ubtP28

📱 WhatsApp: +86 17623790407