How Openhaus’s Design Delivers Comfort & Efficiency in Extreme Heat

1️⃣ Introduction

When you are specifying windows for climates that routinely exceed 40 °C, the material, design and installation of your aluminium windows become critical decisions.

At Openhaus we have ten years of experience in producing aluminium windows for international markets, and we understand how hot-climate conditions influence window performance.

In this guide you will learn how to select aluminium windows that optimise energy-efficiency, reduce internal heat gain and deliver long-term durability in hot regions.

2️⃣ Why Hot Climates Require Special Window Consideration

2.1 Heat-gain through windows

In regions with intense solar radiation, windows can account for a significant proportion of cooling load if the frame and glass allow heat transfer.

Modern aluminium window systems reduce this by using thermal break profiles and high-performance glazing.

2.2 Material-related challenges

Aluminium naturally has high thermal conductivity, which means without proper design the frame can transfer heat rapidly indoors.

Therefore, selecting profiles with thermal isolation and proven performance is essential.

2.3 Durability in hot, dusty environments

Hot-climate sites often involve extreme heat, UV exposure, dust and sand. The window system must resist warping, fading and sealing degradation.

Aluminium windows with robust finish and good design are well suited for these conditions.

3️⃣Key Features for Energy-Saving Aluminium Windows

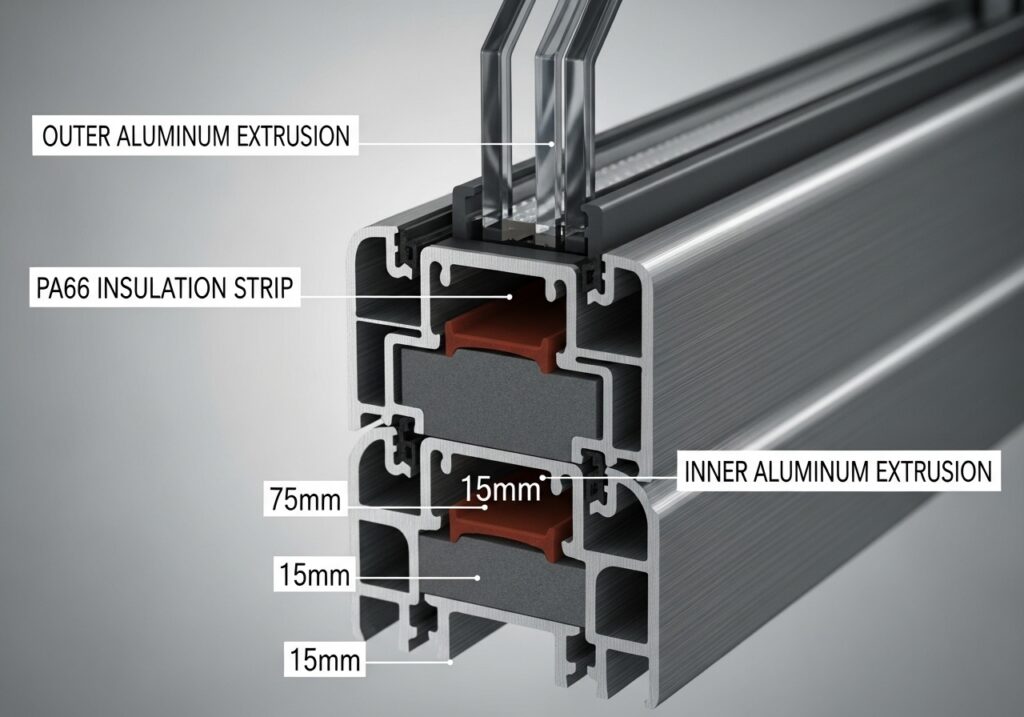

3.1 Thermal-break aluminium profiles

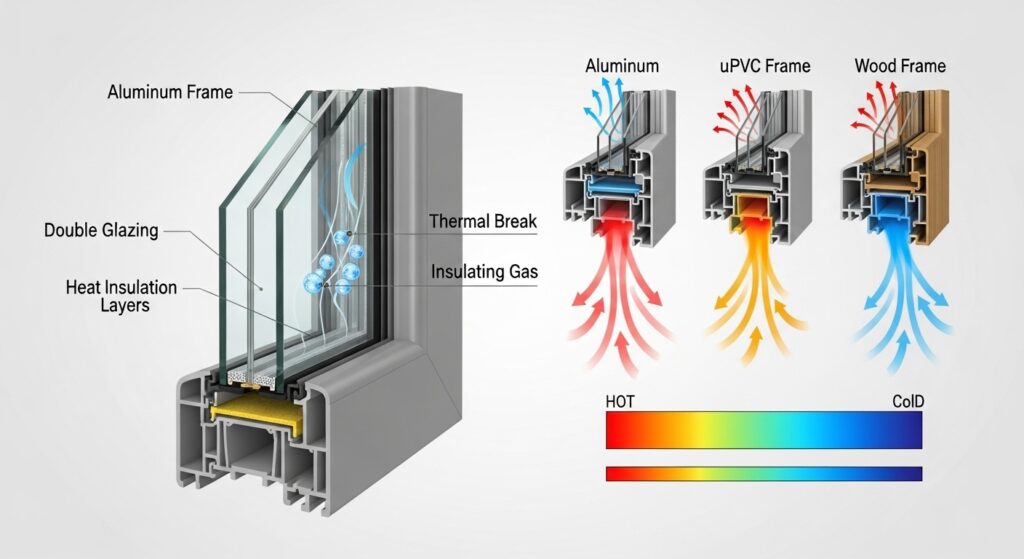

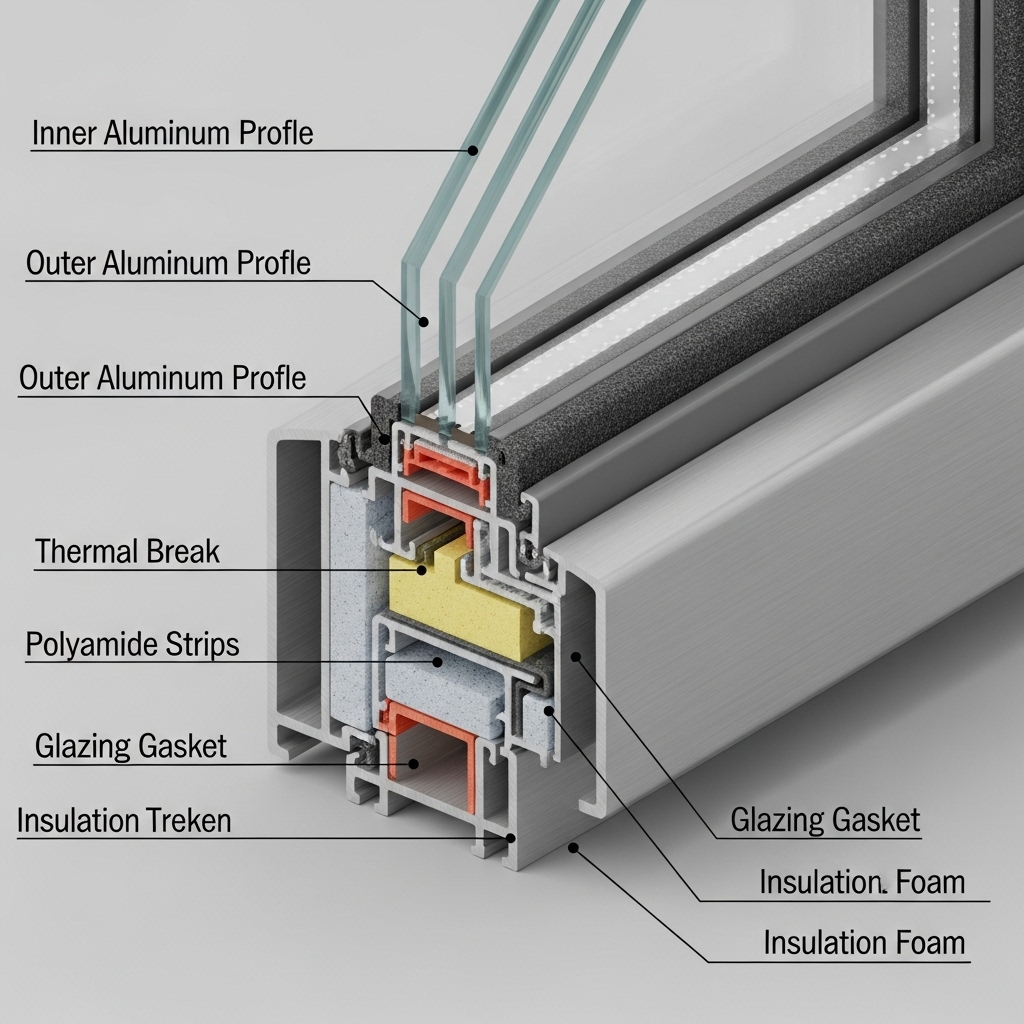

he most important feature for hot-climate energy performance is the thermal break — insulating material inside the aluminium profile that slows heat transfer.

When you request aluminium windows, look for profiles explicitly labelled “thermal break” or “thermally broken”.

Openhaus offers thermal-break aluminium window systems tailored for warm climates.

3.2 High-performance glazing

Glass accounts for a large part of the heat transfer through windows. Double or triple glazing with low-E coatings, inert gas fill and low U-value help minimise heat gain.

In hot regions you may specify glazing with solar-heat-gain coefficient (SHGC) below 0.30.

Openhaus can supply customised glazing options for your project’s climate.

3.3 Superior sealing & installation

Even the best materials fail if installation is poor and sealing is weak. High-quality aluminium windows must feature multi-point seals, tight frames, correct flashing and installation by experienced teams.

At Openhaus we match factory production with clear installation instructions to ensure the field result.

3.4 Durable finishes & hardware

In hot-sun and sand environments finishes must resist fading, chalking and abrasion. Coatings such as powder-coat conforming to AAMA 2605 or anodised finishes are preferred.

Hardware should be stainless steel or marine grade for longevity.

Openhaus sources finishes and hardware specifically for hot-climate export windows.

4️⃣How to Specify for Your Project

- Define the climate zone: desert, coastal, urban high-rise etc. Clarify expected temperatures, solar exposure and wind.

- Ask for the U-value, SHGC, and thermal break details of the window system.

- Request sample units or detailed drawings for review.

- Confirm installation method, ask about sealing, drainage, flashing, and structural anchoring.

- Evaluate warranty, maintenance requirements and thermal performance guarantees.

Openhaus works with international clients to provide documentation and factory support to simplify specification.

5️⃣ Why Choose Openhaus for Hot-Climate Projects

Openhaus boasts ten years of manufacturing experience, delivering aluminium windows tailored to demanding climates.

We invest in thermal-break profile lines, high-grade glazing supply and export-packaged shipment to ensure reliability.

Because we are a factory-direct supplier you gain cost efficiency and direct design input—no unnecessary intermediaries.

Our hot-climate window solutions help clients keep cooling loads down, reduce maintenance and ensure longevity.

6️⃣ Conclusion

To succeed in hot climates you must move beyond conventional window-type thinking and demand systems built for heat, solar exposure and durability.

Energy-saving aluminium windows with thermal break, proper glazing, robust sealing and durable finishes are no longer optional—they are essential.

By choosing Openhaus as your partner, you gain a supplier who understands these demands, delivers engineered solutions and ensures performance in challenging environments.

Let your next project thrive in extreme heat—with aluminium windows designed for it.

📞 Contact Openhaus

📧 Email: openhausliving@gmail.com

🌐 Website: https://openhausliving.com

🔺 YouTube: https://youtube.com/@openhausliv?si=dktMp7xiL4ubtP28

📱 WhatsApp: +86 17623790407